This page discusses water damage testing for the button and screen modules. The buttons will be used more than any other mechatronics component, and are therefore more vulnerable to wear and abuse. For the button module, three water damage scenarios were explored: light splashing, direct flow from one side, and direct flow from above. To quantify water damage, a folded piece of paper was placed inside the enclosure, instead of its actual circuitry. After each test, the paper was examined and photographed.

The button module was placed inside a kitchen sink directly under the faucet. By hand, water was splashed and sprinkled onto the enclosure for 30 seconds to simulate light drizzling or foggy weather conditions. The wet enclosure, after splashing, is shown below.

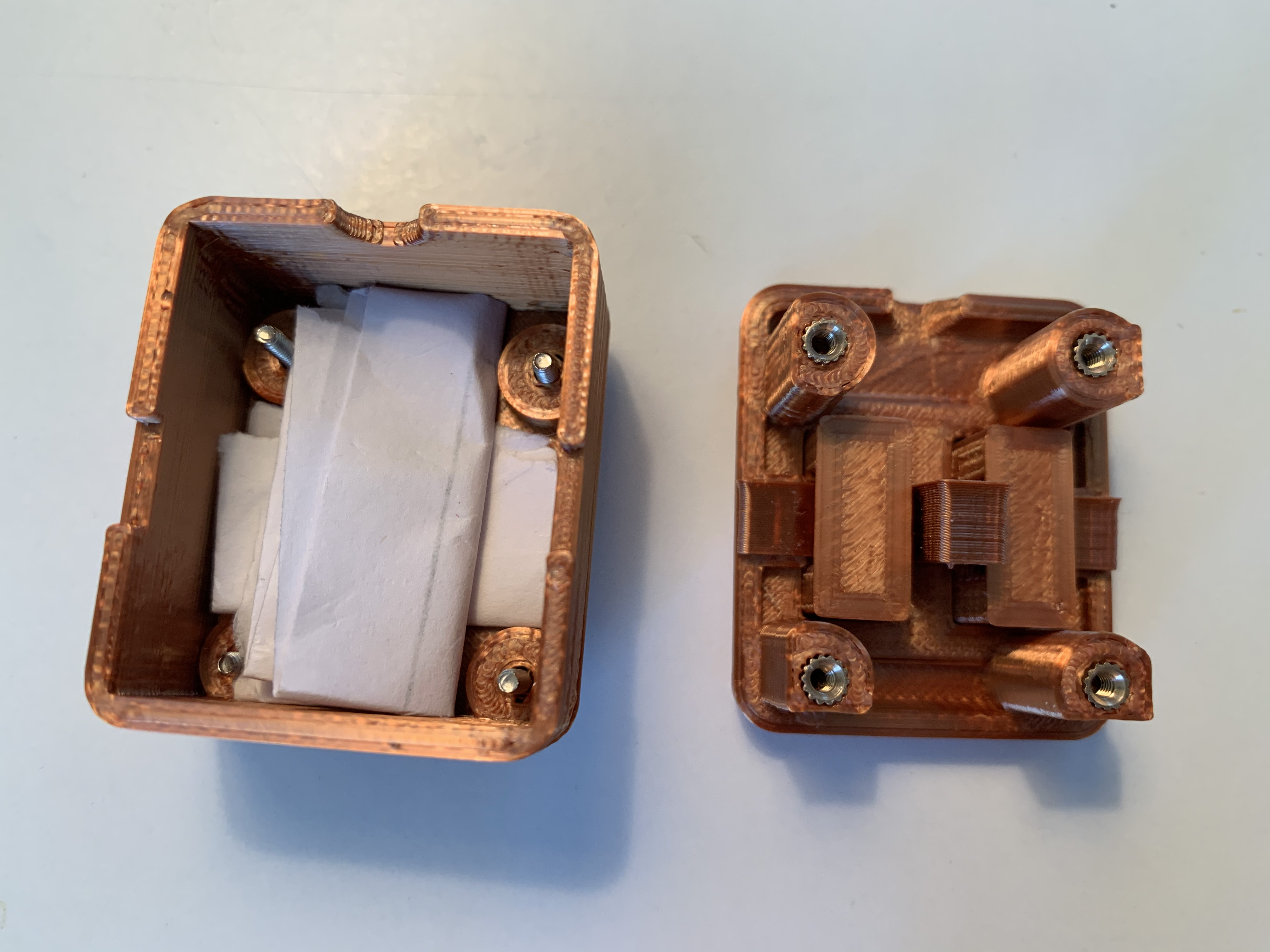

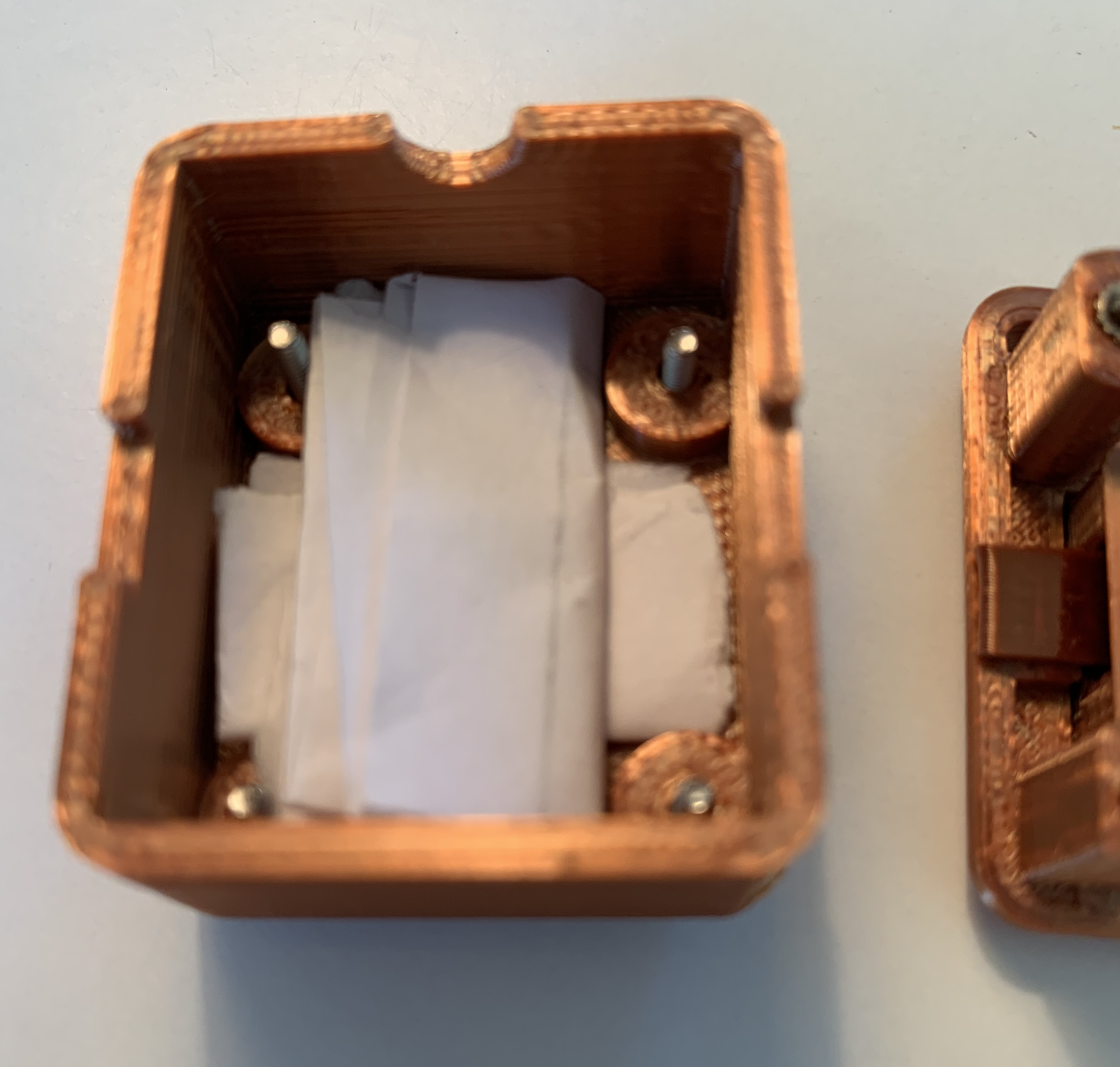

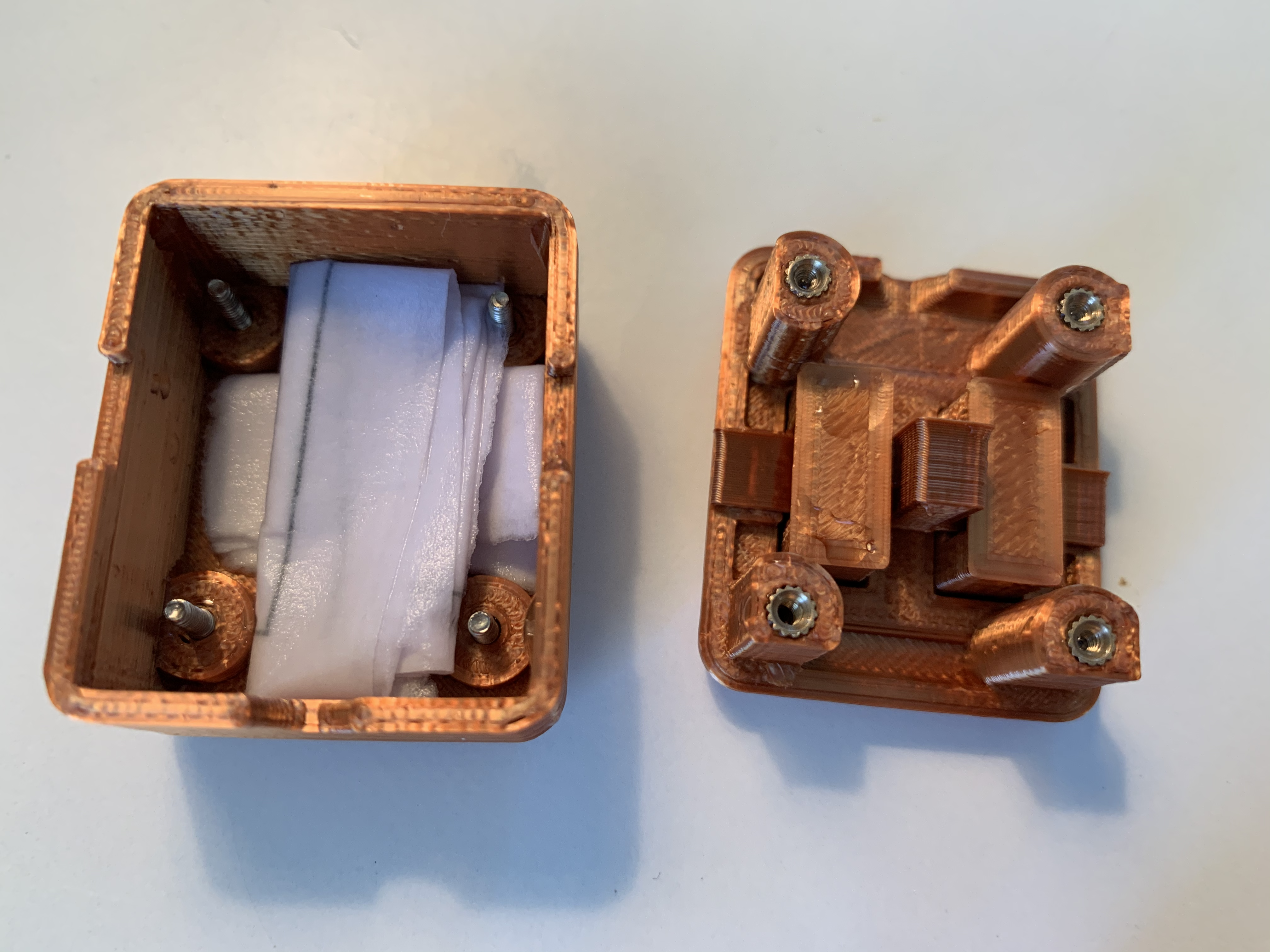

The enclosure was dissabembled and photographed. As shown below, the paper inside the enclosure remained completely dry.

The enclosure was dried before proceeding to the next test.

Next, the enclosure was turned on its side and subjected to 30 seconds of direct faucet flow, which is shown in the animation below.

The enclosure was dissabembled and photographed. As shown below, the paper still remained dry.

Finally, the enclosure was subjected to 30 seconds of faucet flow directly on the buttons, which is shown in the animation below.

As shown in the image below, this test thoroughly soaked the paper.

These tests demonstrate that the button module is not water-tight. It would be unsuitable for use in heavy rain or other wet environmental conditions. However, the contents of the enclosure are protected from indirect splashing and water flow. This indicates that the module would not break from a single instance of splashing from the hydraulic circuit and it would be suitable to use the vehicle on a misty day. It appears that the main source of leakage is in the clearance between the buttons and the enclosure top; the indirect flow test showed that water did not leak through the side seams. To seal the top of the enclosure, a flexible silicon or rubber pad could be glued across the top of the enclosure to cover up the buttons entirely. The pad should be flexible enough to allow the user to still press the buttons. The hole in the enclosure for the wires are a clear source of leakage. An O-ring assembly at this hole, along with protecting the wires in tubing, could also improve its leak resistance.